As the Leister BITUMAT B2 welds a bitumen seam, there is a good chance that the drive roller will be exposed to melted bitumen. If this builds up, it can cause the wheel to lie unevenly against the material surface leading to a poor weld.

The BITUMAT B2 comes with a spare drive roller, which is stored under the circular weight at the front of the machine (opposite the guide bar). To attach this new drive roller, follow these instructions:

1. Unscrew the weight from the front of the machine.

2. Pull the new guide roller out of its holder.

3. Place the welder on its side so that the hot-air blower faces up.

4. Unscrew the brass fastening screw by turning counter-clockwise, and remove.

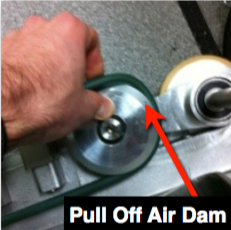

5. Pull the air dam off of the deflector roller.

6. Pull the drive roller up and off of the machine, and then pull the air dam off of the roller.

7. Lay the air dam into the groove of the new drive roller.

8. Align the new drive roller with the post on the machine, and slide it into position.

9. Pull the air dam back over the deflector roller and make sure it lies completely in the groove.

10. Insert the brass fastening screw through the middle of the drive roller and tighten until snug.

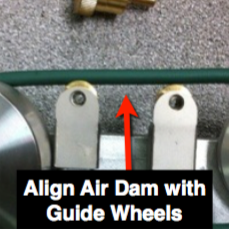

11. Make sure the air dam aligns with the two guide rollers, and then flip the machine back into the proper position.

If you have any questions or are having any trouble with your welder, please contact your Leister authorized service center.

© 2024 Hy-Tech Products, Inc. All rights reserved. Terms of Use