Prior to using the Leister TRIAC Drive, it is recommended to familiarize yourself and your team with the semiautomatic roofing welder's controls. Following is an overview of how to configure the TRIAC Drive's heat and speed settings.

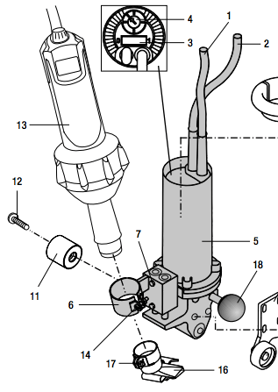

The TRIAC Drive requires the use of a hot air hand tool, specifically the TRIAC AT or ST. The heat is controlled by the hand tool, not the drive unit. The following overview details how to adjust the heat on the TRIAC ST.

Turn the black potentiometer dial to set the heat output.

Turn the black potentiometer dial to set the heat output. The TRIAC Drive's speed setting is set on the drive motor, not the hand tool.

When using the welder, do not push or pull it. Instead let the drive wheel do the work, and simply keep the welder flat against the surface.

While the semiautomatic welder weighs 9 lbs., it still requires the user to firmly press it against the seam. This is especially true for welds on vertical surfaces, such as parapet walls. There is no way to add extra weight to the welder.

If you have any questions, please contact Hy-Tech Products at 800-635-0384, or your local Leister Sales and Service center.

© 2024 Hy-Tech Products, Inc. All rights reserved. Terms of Use